Maintaining Your Chainlink Fence in 2024

When considering fencing options, a common query revolves around maintenance. While wooden fences often suffer from sun exposure, necessitating regular staining, what about chain link?

Residing in the Pacific Northwest entails managing a consistently damp environment, which can have adverse effects on the longevity of your fence. This is why fence contractors strongly advocate for the adoption of Post on Pipe technology to enhance the durability and lasting quality of your fence.

In response to feedback from fence contractors, it has been observed that traditional cedar and pressure-treated posts tend to have a shorter lifespan, particularly when in direct contact with the soil. Standard posts are susceptible to water absorption at their base, especially during rainy periods when water tends to accumulate in that region. This prolonged exposure weakens the lower section of the post over time, resulting in a significantly reduced lifespan for the post and, consequently, a shorter life for the fence.

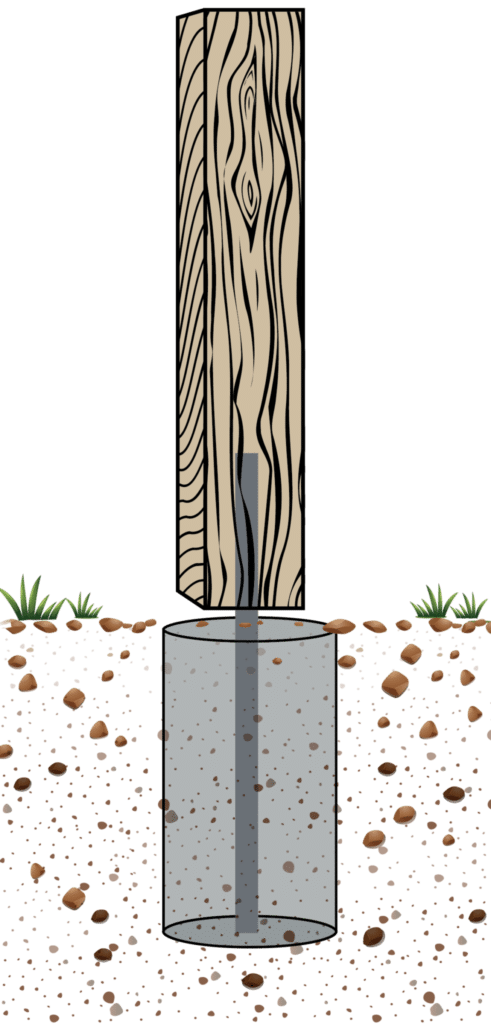

Designed to address this specific issue, the post-on-pipe solution offers an innovative approach. Rather than having the post directly in contact with the ground, the wooden post is elevated, maintaining a recommended clearance of 2-3 inches above the ground. Meanwhile, a durable galvanized pipe is securely embedded 2 feet deep into the soil through the concrete foundation, providing robust support and stability to the post. This clever engineering not only mitigates potential ground-related concerns but also ensures a reliable and long-lasting solution for your project.

Additionally choosing Post on Pipe over a standard post becomes apparent when considering the ease of replacement. Unlike standard posts cemented into the ground, which pose a significant challenge when they rot or snap, Post on Pipe offers a remarkably streamlined solution. In the case of standard posts, the arduous task of digging out the concrete is required for replacement. However, with the Post on Pipe technology, the process is notably simplified. When an old post needs replacement, it can be effortlessly removed from the pipe, and a new post can be promptly affixed to the existing pipe. This not only reduces the labor-intensive nature of the task but also ensures a quicker, more efficient replacement, making Post on Pipe a practical and time-saving choice for those seeking a hassle-free fencing solution.

The Post on Pipe solution offers the flexibility of both pressure-treated and natural clear cedar posts. When deciding between pressure-treated wood and cedar for your construction and outdoor projects, it’s essential to consider the following distinctions:

1. **Treatment:** Pressure-treated wood undergoes chemical treatment to guard against rot, insects, and decay. On the other hand, cedar boasts natural resistance to these elements.

2. **Cost:** As a rule of thumb, pressure-treated wood is the more economical choice for outdoor projects like decking, fences, and retaining walls when contrasted with cedar.

3. **Appearance:** Cedar’s inherent rustic charm appeals to many with its natural look, while pressure-treated wood tends to exhibit a more uniform appearance due to the treatment chemicals.

4. **Environmentally-Friendly:** Consideration for the environment favors cedar over pressure-treated wood. The potential environmental harm caused by the chemicals in pressure treatment highlights the eco-friendly attributes of cedar. Being a renewable resource, cedar ensures a sustainable and responsible choice for those looking to minimize their environmental impact.

PREPARE THE SITE: Ensure the area is level and free from obstructions. Use a post-hole digger to create a hole of 6-8” diameter and 20-24” depth. The concrete mixing involves multiple steps and people. Mix concrete inside the hole in layers while keeping the post upright and level. Begin by pouring a few inches of water, then add concrete mix. Stir and press together while maintaining a level. Repeat until the hole is filled. Optionally, create a concrete cone for better water dispersion.

So why go Post on Pipe vs regular posts? In Summary, if you’re looking for a resilient and long-lasting fence option, Post on Pipe stands out as an excellent choice. This solution presents several advantages compared to traditional pressure-treated posts, and its technical specifications guarantee reliable stability, easy replacement, providing reassurance for your investment in the future of your fence.

When considering fencing options, a common query revolves around maintenance. While wooden fences often suffer from sun exposure, necessitating regular staining, what about chain link?

Post on pipe is a total game changer for the residential fence industry here in Western Washington and I couldn’t be happier about being able

At Everguard, we believe in straightforward lumber delivery terms designed to provide you with a hassle-free experience. Here’s a closer look at our delivery process.